Introduction

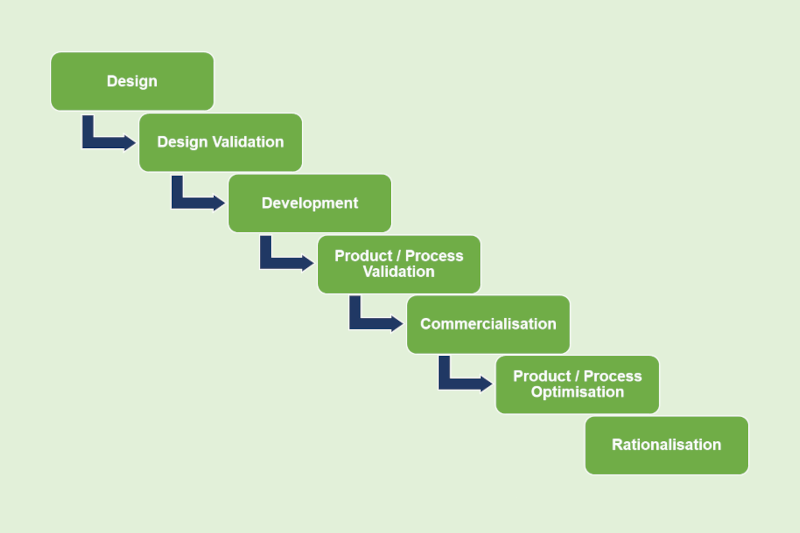

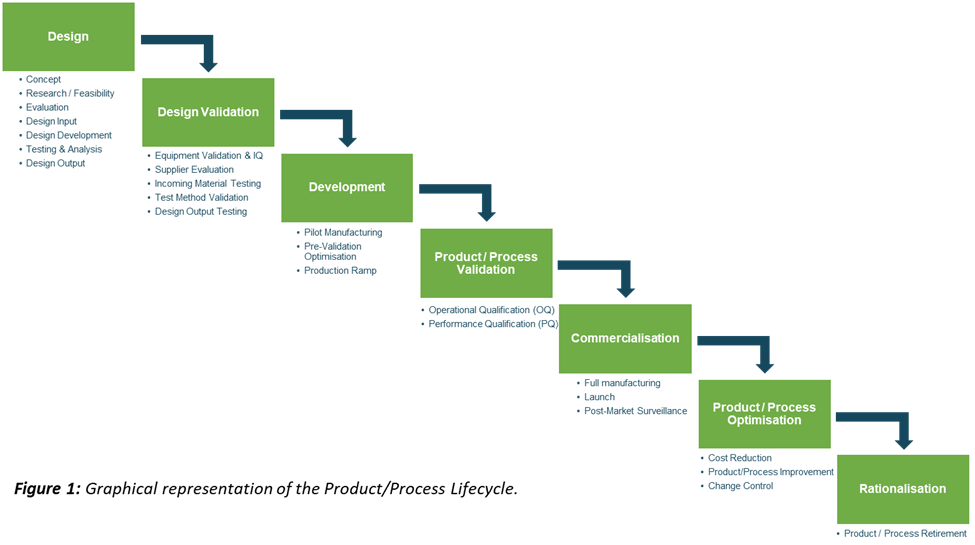

Product (and/or process) lifecycle is the time from initial concept to retirement of a given product. There is a significant level of activity occurs in the intervening period, much of which happens before the product ever comes to market. There is a lot of literature out there that breaks this activity into four very broad categories; Introduction, Growth, Maturity and Decline. Some will add additional categories such as development, saturation etc. Rather than focus on categories, this paper will attempt to break down the product lifecycle into the relevant processes that a company must consider when planning to bring a new product to market. Elements of this paper can also be used when making changes to existing products.

Figure 1 below graphically illustrates the seven processes that form the product lifecycle. While this may look significant at first glance, there are an infinite number of variations on how it can be completed and the order in which it is done so. The level of timing and resourcing required for each process depends upon the given situation. For example:

- Overlap between process is possible and even encouraged if well-planned.

- The run order of design validation and pilot production can be reversed.

- You would typically expect pharmaceutical products to legally require more validation activity than say, common household items.

- Products being leveraged from a previous product should require less design time.

- If the company does not already build similar products, then setting up of the manufacturing line/operation may be a major activity.

The process illustrated above is iterative. At any point, you may discover that you cannot proceed without stepping back to the previous process and making changes. The remainder of this paper will look at each of these 7 processes in more detail.

Design

Figure 2: Elements of the Design Phase, required before proceeding to Design Validation.

Concept:

Design starts with an idea, a concept that solves a problem. This includes improving an existing product/process or developing a superior product. Once you have this, you should document all the key features, drawings, dimensions and anything else that is currently known about product. While this is important, don't agonise over it too much because you will find that you will make changes during subsequent revisions of the design process as you learn more.

Research / Feasibility:

This involves determining feasibility of the design from both a practical and marketing point of view - can it be built in a cost-effective way, does the market want it, who are the target audience, how much are they willing to pay for it etc? A prototype is a good idea at this point because it allows you to verify feasibility in a physical sense, solicit user feedback and get an appreciation of the visible attributes of the product. Finally, a patent search is important so that you do not waste valuable time, money and resources on your concept, only to later find that you cannot proceed with.

Design Evaluation:

Complete your design evaluation. Once the design evaluation is complete, the design inputs can be generated. A thorough evaluation should include:

- Criteria used to judge the design. Depending on the industry, it may be required to proceduralise the must-have items.

- The standard that must be achieved against the criteria for the design to be deemed successful.

- Evidence that such standard has or has not been achieved.

- Conclusions about the design – benefits, risks and assumptions going forward. This includes any changes / updates that are required.

Design Input & Development:

For highly regulated industries (e.g. medical device), the manufacturer is responsible for ensuring that the design inputs are appropriate in addressing user needs. Design inputs are deemed to be the physical and performance characteristics of a device that are used as a basis for device design and consequently, manufacturers are obliged to establish and maintain procedures to this effect. Design development is essentially about further improving the design.

Testing & Analysis:

As the name suggests, this phase is about testing and analysing the design. The result of which is the determination of the design outputs. A robust test method design is important here prior to completing any testing to ensure that a test method is suitable for its intended use. The test method will need to be validated and this will be discussed further in the design validation section.

Design Outputs:

According to the Food and Drug Administration (FDA), design outputs are the results of a design effort at each design phase and at the end of the total design effort. Similar to design inputs, highly regulated industries oblige manufacturers to establish and maintain procedures around design outputs. These procedures, along with items such as specifications and drawings are examples of design outputs. More on design outputs later when we discuss design validation.

Design Validation

Figure 3: Elements of the Design Validation Phase, required before proceeding to Development.

Equipment Validation & IQ:

Equipment validation at this point may be a requirement for regulatory compliance. However, done correctly, it can be beneficial in preventing future costs for the manufacturer. Given that validation is essentially an evidence-based affirmation that the equipment can consistently and reliably achieve predetermined specifications, then a robust and documented validation should eliminate the need for in-process testing and controls.

The first step is to establish and document the intended use (user requirements). A risk assessment should then be completed prior to installation of the equipment per the required specifications. For off-the-shelf equipment, this is usually the manufacturer’s recommendations. At this point, the Installation Qualification (IQ) may be executed. This involves confirmation through objective evidence that the equipment has been installed and configured per specifications.

Supplier Evaluation / Incoming Material Testing:

Like equipment validation, supplier evaluation and testing of incoming materials may be a legal requirement and again, if done correctly, can be a forward-looking cost prevention measure. At this point in the process, you've probably already determined the quality requirements of the product and identified material suppliers. If you are in a highly regulated industry, you need to certify these suppliers and implement a quality service level agreement to ensure incoming material meets a pre-defined standard. If not, it’s still good practise to evaluate your suppliers because it may reduce incoming defects and cycle times in the future.

Similarly, you may need to implement a receiving inspection process to test incoming material and verify the health of your supplier’s testing practises. Any material that fails to meet specification should be rejected and a corrective action plan agreed with the supplier.

Test Method Validation:

We've already discussed testing and analysis in the design section. Now, we need to talk about test method validation because we need to confirm that the test method is suitable for its intended use. A typical test method will use equipment, materials and a testing process. For validation purposes, these all need to be included in a series of experiments using the given test method for routine sample analysis. The results of these experiments are statistically analysed to determine if they can consistently and reliably achieve predetermined acceptance criteria. If they can, then the test method is deemed to be valid.

Design Output Testing:

This section concerns itself with testing the critical design outputs and ensuring that they meet the acceptance criteria. It can sometimes be difficult to determine which design outputs are deemed to be critical. One way is to ask yourself if a given output is essential for the product to function correctly? If so, then it's likely to be a critical output.

In summary, design output testing is ensuring that the product specifications meet user needs and intended use. Testing here is a collective term for testing, inspection and analysis. Although there can be similarities, it is different to the overall product/process validation which we will get to later. At this point, only to design is being tested and not the process.

Development

Figure 4: Elements of the Development Phase, required before proceeding to Product/Process Validation.

Pilot Manufacturing:

Pilot manufacturing may begin prior to, or overlap with, the design validation stage. Pilot manufacturing is when the product design is transferred into manufacturing specifications, basically making it the start point for full scale manufacturing. In some companies, this phase will be the handover point from R&D to the commercial manufacturing team.

The benefit of manufacturing on a pilot scale is that it minimises risk. Pilot manufacturing often exposes potential difficulties in the process that would be very costly if they were not found until later. Examples include quality, efficiency, material yield and cycle time issues. Do you really want to be finding out about a major issue in one of these areas at the commercialisation stage? Informing top level management (or maybe even the customer) of that would be quite the difficult conversation!

Pre-Validation Optimisation:

The structure, efficiency and capability of any manufacturing process will impact upon the cost of that process and the quality of product that results from it. Therefore, good process is key to reduced cost and better product quality. Processes can be improved upon at any point in their lifecycle through the practical application of modern-day quality management programs such as Six-Sigma. So, if you have encountered issues, potential issues or simply found opportunities to optimise the process during the pilot manufacturing stage, then now is the time to make those changes.

Production Ramp:

Production ramp is when a company increases its production, typically ahead of anticipated demand increase. Sometimes, as is the case here, this will be prior to validation and commercialisation of a new product. This is not something that should be underestimated and planning should commence in plenty of time (don’t wait until after the pilot manufacturing step). Ramping up production requires consideration of many items and ensuring that there are enough materials, equipment, tooling etc available two facilitate the ramp. Most importantly of all, you need to ensure that you have the right people with the necessary skillset in place

Product / Process Validation

Figure 5: Elements of the Product/ Process Phase, required before proceeding to Commercialisation.

Operational Qualification (OQ):

The Operational Qualification (OQ) phase is where you verify and document that the manufacturing process is achieving its operational requirements (i.e. within the predefined operating ranges). This is achieved via random testing from a series of manufacturing builds, where the upper and lower extremities of the in-process specifications were used. The outputs of the testing are statistically analysed to determine if they can consistently and reliably achieve predetermined acceptance criteria. If they can, then the OQ is deemed to be successful.

Performance Qualification (PQ):

The Performance Qualification (PQ) is the final validation phase, where you verify and document that the manufacturing process is performing as anticipated when operating in conditions similar to what is expected during regular, commercial manufacture. Again, this is achieved via random testing from a series of manufacturing builds except this time, under normal operating conditions. Similar to OQ, the outputs of the testing are statistically analysed to determine if they can consistently and reliably achieve predetermined acceptance criteria. If they can, then the PQ is deemed to be successful.

Commercialisation

Figure 6: Elements of the Commercialisation Phase, required before proceeding to Product/ Process Optimisation.

Full Manufacturing:

Earlier, we discussed ramping up production as part of the development phase prior to validation. Reaching full manufacturing is simply the result of that. You are now either operating at the capacity you wish to operate at or you’re operating at maximum capacity if you've run out of resources, floor space etc.

Launch:

Product launch means different things to different people. For most, the phrase probably conjures up images of Apple’s iPhones or other hi-tech gadgets. Perhaps you think about marketing and attracting customers? Yes, that’s all part of it too. However, for the purposes of this paper, we will focus on the activity that needs to happen internally within the commercial manufacturing team prior to a launch.

A product launch is a process, not to be considered as an isolated event. It needs to be a planned and coordinated effort. Everybody within the company needs to know about the new product and understand the criticality of it. A product launch plan detailing the sequence of events, timelines and milestones is a must. Planning should start well in advance and allow plenty of time to rectify anything that might go wrong, without impacting the launch date.

Regarding manufacturing/processing of the product itself, additional diligence is required. Remember, this is a new product going to market and first impressions will matter. It is important that everybody involved in the building of the product along with those involved with its release are giving it due care and attention. After all the hard work to bring it this far, getting it wrong at this point could be detrimental to the future of the product.

Post-Market Surveillance:

Post-market surveillance is the structured monitoring of safety and performance of the product, following its release onto the market. Monitoring is performed by the manufacturer and achieved through proactively collecting and reviewing data. For safety reasons, it is a legal requirement in the pharmaceutical and medical device industries. This is because monitoring the product in the real world, using actual evidence from a larger population, offers far more data/information than what was possible to collect previously, therefore providing a more complete picture.

While it may not be a legal requirement, this practise is also recommended across other industries as a means of getting feedback on product performance. In fact, collecting and reviewing data throughout a product’s lifetime in the market should:

- Improve early detection of issues.

- Facilitate understanding of market share opportunities.

- Enable product and process improvements that are directly related to the customer experience.

- Provide valuable information prior to planning the next generation product.

Product / Process Optimisation

Figure 7: Elements of the Product / Process Optimisation Phase, required before proceeding to Rationalisation.

Cost Reduction:

Identifying, quantifying, prioritising and planning cost reduction opportunities for your product is important to remain competitive. Typically, the value of a product will reduce over its time on the market. Therefore, to maintain margin, you need to reduce the cost of getting that product to the market.

There are many ways to approach this and we recommend that you read our white paper on it. However, we have given a taste of some of the opportunities below:

- Product and process improvements (see next section).

- Material usage reduction: Greater Yield = Greater Profit

- Lean Six Sigma and continuous improvement programs.

- Robust quality systems that minimise complaints and product defects.

- Good cost leadership.

Product / Process Improvement:

Previously, we looked at Pre-Validation Optimisation. At that point, we weren't discussing full commercial production. However, the basic principle remains the same, “The structure, efficiency and capability of any manufacturing process will impact upon the cost of that process and the quality of product that results from it. Therefore, good process is key to reduced cost and better product quality. Processes can be improved upon at any point in their lifecycle through the practical application of modern-day quality management programs such as Six-Sigma”.

The fact that we're now at a different point in the overall product/process lifecycle is not relevant. If you are encountering issues, potential issues or finding opportunities to optimise the process with a tangible return on investment, then make those improvements. Some general examples of how this can be done include:

- Developing bespoke tooling for greater accuracy and efficiency.

- Poka Yoke (mistake-proof) your processes.

- Improved product changeover techniques such as Single Minutes Exchange of Dies (SMED).

Change Control:

Change control is critically important when optimising your process. At its worst, failure to manage change can result in a product or process operating outside of its validated range, leading to quality and compliance issues that could be ruinous for the business. While things may not get this bad, it is true that change done poorly can bring disruption to an organisation at high financial cost. This will often be direct (e.g. causing production down situations) but can also be indirectly affecting productivity and morale through the irritation and resentment of failure.

In summary, change is necessary for a business area to stay current and remain relevant but it needs to be carefully managed so that it is understood, planned, implemented and communicated in a structured and seamless manner.

Rationalisation

Figure 8: Rationalisation – the final stage of the product / process lifecycle.

Product / Process Retirement:

The final stage in the product life cycle is product rationalisation. Product rationalisation is reducing the number of products or stock-keeping units (SKUs) that a business manufactures or produces, either because they are negatively contributing to strategic goals or because the business wishes to invest in its more lucrative products. Simply put, it is the retirement of products or SKUs.

In many companies, products at the end of their lifecycle are not managed with the same degree of focus and attention as they are during other stages of the cycle. This is a failing and should be addressed because the protracted life span drives up cost via:

- Increased business complexity.

- Manufacturing inefficiencies (shorter production runs & increased setups).

- Hardware / software obsolescence.

- Growing Supply Chain complexity leading to increased inventory and associated costs.

- Lost benefit of material economies of scale and buying leverage.

- Lost sales of the newer, more lucrative product because customers refuse to upgrade when the necessity isn't there for them.