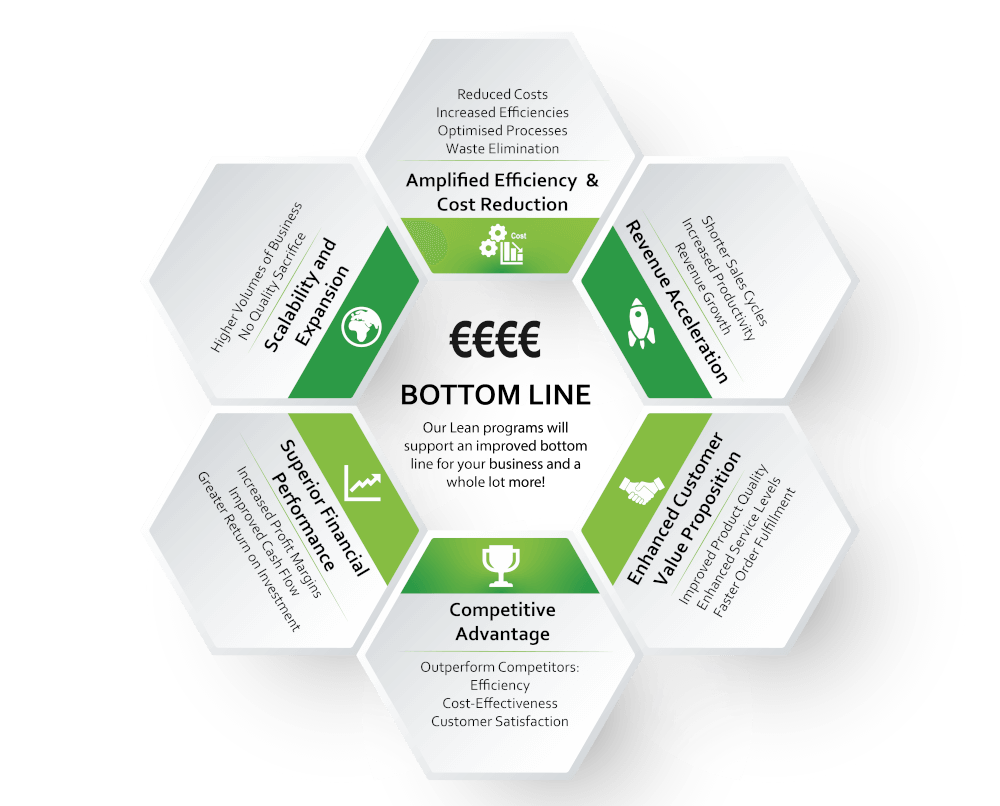

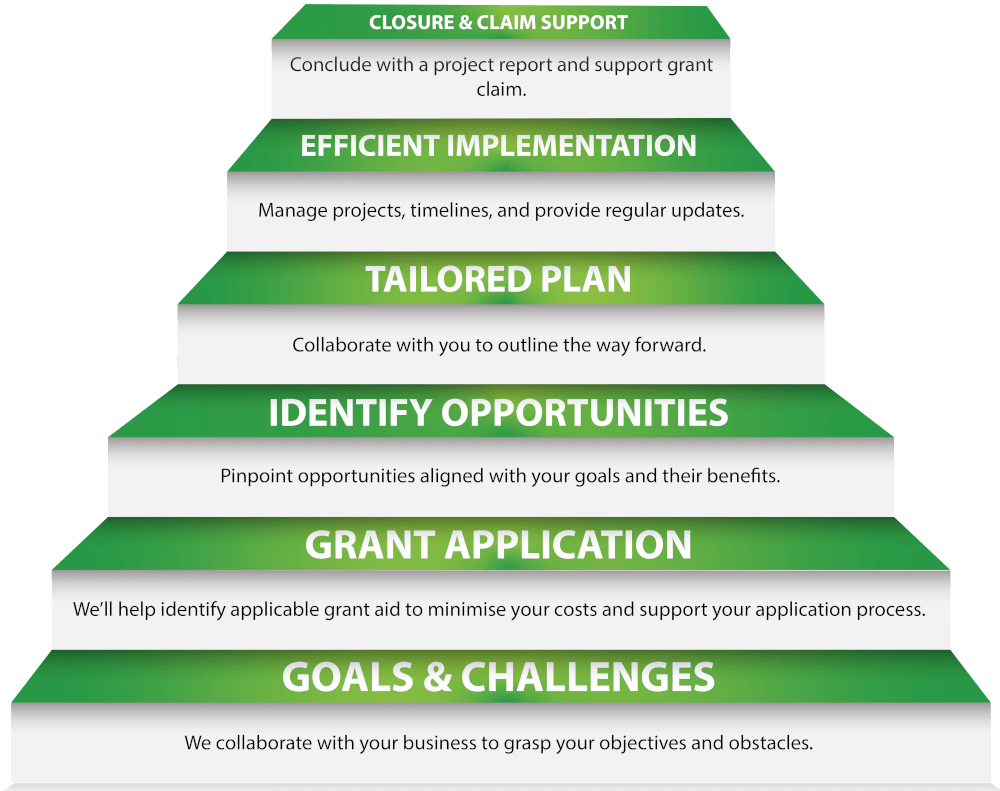

CMP Solutions will design and implement both capital and operational cost-reduction plans / strategies for your organisation. We will do so in a way that encourages the sustained growth of your business via improved standards of Quality and Customer Service, while preserving Employee satisfaction.

Contact us today and we look forward to positively influencing your cost reduction journey!