Introduction

In order to remain competitive in the ever-evolving and challenging business environment, companies need to deliver year-on-year cost savings that are sustainable and don't negatively impact on company performance. However, this is easier said than done. There are a lot of considerations when approaching a cost reduction journey, namely what do you focus on?

- Approach: “quick wins” versus investing in sustainable longer term cost reductions.

- Area of focus: Productivity, quality control, waste reduction etc.

- Do I make blanket cuts?

- Ratio of capital to operational cost-cutting.

Vision and Strategy

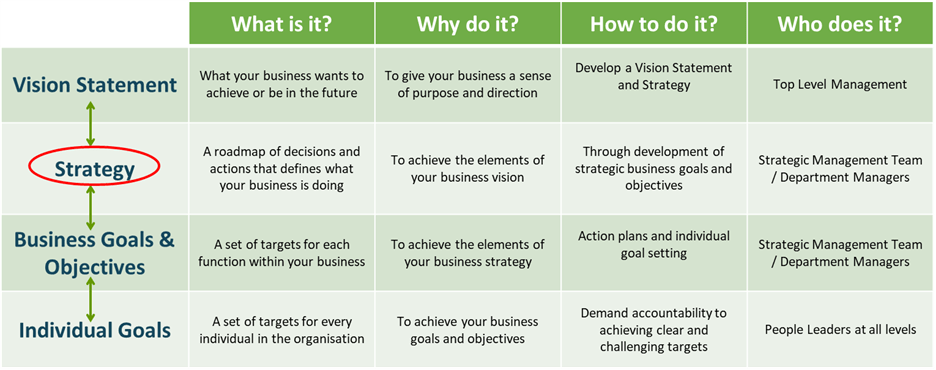

A good starting point in answering this question is to understand what your business is trying to achieve in the medium to Long-Term. Does your organisation have a vision statement accompanied by a good strategy to realise this vision over the next 3 to 5 years? If so, this should dictate the level of cost reduction activity. For example, if your product is luxury/bespoke and high margin (e.g. Rolls-Royce), then strategically, cost reduction will not feature as substantially as quality or customer service. Conversely, for a low margin commodity product where cost competitiveness is critical (e.g. baked beans), you will typically see unit cost as a leading item in the business strategy.

Figure 1: Unit Cost is typically part of the business strategy of a company where cost competitiveness is critical.

Therefore, prior to attempting a cost reduction journey, it is important that your company has a vision statement and that unit cost is appropriately allocated to the business strategy. Without it, misalignment may occur in relation to where cost reduction ranks relative to other priorities. This can result in focus in the wrong areas and failure in all!

Cost Reduction as a Strategy

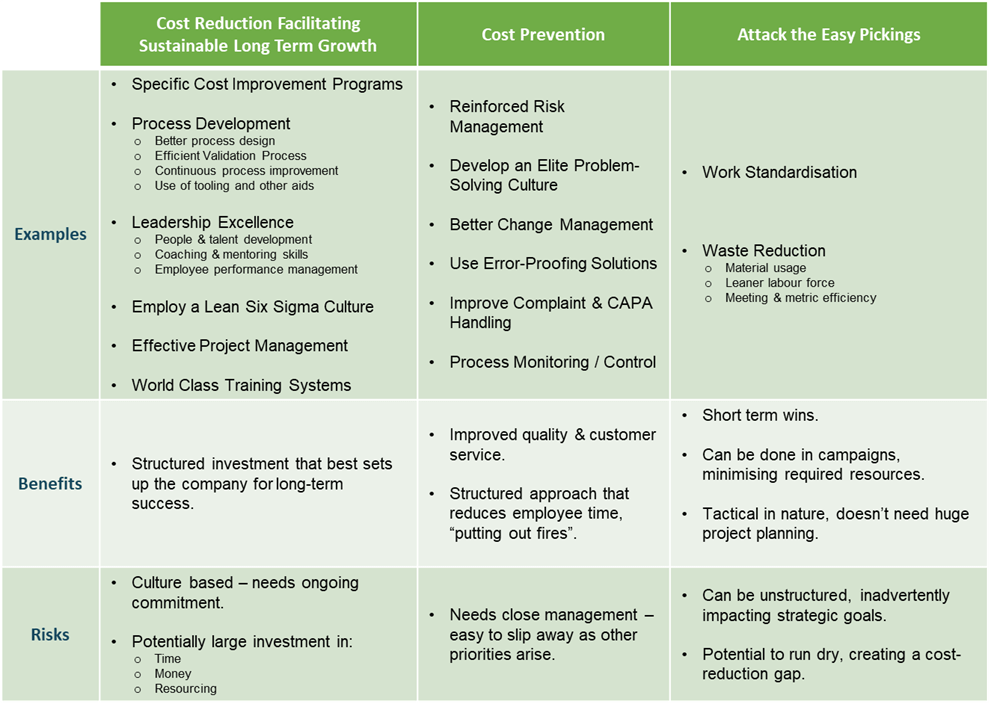

Now that we have addressed the relationship between business strategy and unit cost, the remainder of this paper will assume that aggressive cost reduction is indeed part of the strategy of our hypothetical company. From Figure 1 on the previous page, we know that the next step is to set business goals and objectives. However, the difficulty is that that you may not have existing cost saving ideas for the purpose of setting these goals. Figure 2 lists a number of high-level suggestions to get started. Although categorised for simplicity purposes, it is important to know that the categories are not mutually exclusive. Overlap is recommended for your business. These suggestions are explained further in the following pages.

- Cost Reduction Facilitating Sustainable Long-Term Growth: Strategic approaches, necessary for any well-managed company committed to investment in its future.

- Cost Prevention: Also strategic in nature, this category refers to unplanned costs that occur because of poor risk management and/or an inability to expertly problem-solve and prevent potentially costly issues.

- Attack the Easy Pickings: The low hanging fruit that typically has tangible and obvious benefits. Excellent to provide short term returns for your business but caution advised – need to avoid the cost of any potential clash with the strategic goals of the business.

Figure 2: Categorised cost improvement examples with potential benefits and risks.

Cost Reduction Facilitating Sustainable Long-Term Growth

- Specific Cost Improvement Programs:

• This is the creation of effective cost improvement programs tailored for your business. Such solutions should identify, quantify, prioritise and plan the full range of cost reduction opportunities in your company, ensuring the most efficient approach is taken. Done well, both short-term cost reduction and long-term growth are considered, thereby transforming your financial results now and into the future. - Process Development:

• Plenty of opportunity should present itself through optimisation of your processes during any/all stage(s) in the process lifecycle. This can be done by means of practical application of modern-day quality management programs such as DMAIC.

Exceeding your quality and customer service requirements while overcoming excessive cost and time constraints. This should be the goal while getting your product/process through the validation and verification process, to full commercialisation as quickly as possible.

Empower your employees to gradually improve the efficiency of their work processes by impressing upon them that their ideas are important and providing them with the tools required to drive these efficiencies. Through the introduction of structured and sustainable continuous improvement programs, this goal can be accomplished and give your company a competitive advantage.

• Use of tooling, fixtures and other aids for faster processing times, reduced in-process material losses and greater machining accuracy. In summary, greater productivity with improved quality and reliability. - Leadership Excellence:

• Design and implementation of sustainable talent development solutions for your company. These should look to understand the areas where employees want to develop new skills and grow their knowledge and match them to the areas the company deems there to be a void. Plans should then be created to nurture the progression of the employee's development through the facilitation of learning opportunities. This will create win-win scenarios where employee engagement and productivity increases, while the company rectifies potential gaps in knowledge, skills and succession planning.

• An empowered and employee-led organisation will always out-perform a more directive and controlling company long-term. Coaching is a sustainable approach to get the best possible results from your employees and is becoming increasingly popular in all industries. The alliance between the coach and coachee can be extremely effective at embedding cultural change. The coach empowers the coachee to find the answers within themselves and the coachee is empowered to unlock and achieve their full potential.

• Customised mentorship programs that will train mentors and mentees to have productive conversations and meetings, providing them with development tools and resources to improve performance and accomplish set goals. An inclusive mentoring culture should be developed, centered on learning, sharing new ideas and creating a shared vision, thereby enabling numerous benefits to be realised such as increasing employee engagement, retention rates and skill development.

• Create a tailored performance management program for your business. Analyse what is and isn't working for you today and based on this, implement a plan for the future. Performance management shouldn't be, as it often is, a topic with negative connotations. The goal should be to create a positive experience by not merely enhancing the performance of individuals, but holistically improving engagement and morale across your business. - Employ a Lean Six Sigma Culture:

• Use Lean Six-Sigma principles to implement the relevant process improvement techniques and tools that will minimise variation and eliminate defects from your business. - Effective Project Management:

• Schedule/cost overruns, poor risk management, scope creep, demotivation of team, bad reputation – these are just some of the vast array of perils that have befallen many a project leader and led to the termination of otherwise valuable projects. If project management is an issue in your company, it may be wise to employ the knowledge/expertise of experts in structured project planning and execution. They can drive the activity that will ultimately achieve your project goals within the given constraints. - World Class Training Systems:

• Develop a best-in-class training system for your company that will be in-line with your business strategy. Your training system should reduce the time it takes to train employees, while ensuring consistency across your training process. Clearly-defined objectives and learning outcomes for all are a must and metrics to get visibility on the effectiveness of the training program are also recommended.

Cost Prevention

- Reinforced Risk Management:

• Risk Management systems and processes are designed to protect businesses from product quality and compliance risks. Failure to implement appropriate risk management can be fatal to your business or can lead to legal action (both personal and against the company), death/injury/illness, fines, reputational damage and product recalls. Suffice to say, reinforcing your risk management system integrating contemporary risk management tools into your business can prevent costly and unnecessary issues. - Develop an Elite Problem-Solving Culture:

• If your organisation is seeing the same problems arise repeatedly and you’re treating symptoms instead of systematically preventing issues then you have a problem-solving deficit. Poor problem-solving may manifest itself in your organisation through reduced outputs, operational inefficiencies, material waste, increased defects and excessive cycle times. These challenges are opportunities to develop the problem-solving skills of your people. Effectively applying data/fact-driven improvement methodologies and using root cause analysis tools will resolve any problem, whether it be technical, behavioural, logistical or otherwise. The best part is, you will have the dual benefit of resolving your challenges, while in parallel upskilling your people with a valued competence. - Better Change Management:

• Every manager knows that change is necessary for a business area to stay current and remain relevant. Unfortunately, change done poorly has the opposite effect and the disruption it brings to an organisation can come at a high financial cost, both directly and indirectly by affecting morale through the irritation and resentment of failure. Therefore, management of the dynamics of change and fostering a culture of excellent change management using a structured approach is key to the understanding, planning, implementation and communication of seamless change. - Use Error-Proofing Solutions:

• Poka-Yoke (or mistake-proofing) is a lean manufacturing concept used in the workplace to prevent human error. There are endless examples of Poke-Yoke solutions in society and one that everybody is familiar with is the standard 3-pin plug – it has a single method of operation (i.e. cannot be incorrectly plugged into the socket). Development and implementation of mistake-proof solutions for your error-prone processes will eliminate defects and ensure right-first-time outcomes with higher standards of quality and reliability for your product, saving your business time and money. - Improve Complaint and CAPA Handling:

• Improve your Complaint and CAPA Handling system, keeping compliance to regulatory requirements in mind. This is achieved through the identification of the issue or potential issue, collection of facts and data, investigation and identification of the cause(s) and implementation of corrective/preventative actions to avoid occurrence/recurrence. Using recognised statistical methodologies and problem-solving tools, this will not only prevent the potential occurrence or recurrence of costly quality issues and complaints leading to loss of business but will likely see new customers being referred to your business. Why? Because your now thorough understanding of root cause and use of a process that promotes the implementation of corrective actions will demonstrate proficiency and professionalism, thereby impressing clients. - Process Monitoring / Control:

• Process monitoring involves the scrutiny of measured data (e.g. pressure, temperature, force) to establish the current state of the process. Statistical Process Control (SPC) uses statistical techniques to control a process by reducing variation. Both are methods of quality control that typically use tools such as run charts and control charts together with a reaction plan. When operated efficiently, process monitoring/SPC will drive reductions in scrap, rework and general waste, potentially avoiding steep costs.

Attack the Easy Pickings

- Work Standardisation:

• Standard Work establishes the most efficient method of performing a task and implements a specific set of rules/steps to ensure the task is executed in the same manner every time, regardless of who performs it. By dissecting current-state work practices, non-value activity can be removed and a more efficient work sequence created. You can then begin to enjoy benefits such as:

° Repeatability: Enabling positive, predictable and measurable results.

° Less waste and reduced human error and defects.

° Simplified Processes: Facilitate opportunities for further improvement, better problem solving and faster training / onboarding.

° Employee Engagement: Frontline employees are invested and therefore want the best approach. Less hindered leaders can focus more on strategy. In both cases, creativity is encouraged and current stresses reduced. - Waste Reduction:

• Excessive usage of materials/supplies is a waste that could be driving significant cost for your business. It may also be a signal of an underlying Quality deficit. Every component, sub-assembly, material or supply item that is scrapped directly costs your business. The equation is simple, "Greater Yield = Greater Profit". Implementation of a strong yield management process will quantify your losses, analyse their source and generate/implement a process that will increase yield, consequently reducing costs directly.

• Increase the efficiency and productivity of your employees by identifying and eliminating non-value activity. Done well, workforce motivation improves in line with increasing employee engagement, less human error and the elimination of meaningless and frustrating, non-value tasks. For the company, maximising output with less effort and error enables additional, value-adding tasks/projects to be taken on, without the need to hire additional staff.

• Meetings are critical to the success of your business as they are an effective communication tool. Sharing of information and ideas, alignment, strengthening relationships and showcasing leadership are just some of the benefits. Similarly, metrics are important for setting benchmarks of excellence in performance. However, it is also true that too many meetings and metrics (or those done poorly) suffocate productivity and stifle creativity. It can be difficult to quantify the benefit of developing a meeting/metric strategy that achieves your objectives, without impeding the efficiency/ingenuity of your people. However, if you are successful in doing so, it could give your company significant and unexpected benefits!

Setting Business Goals and Objectives the SMART Way

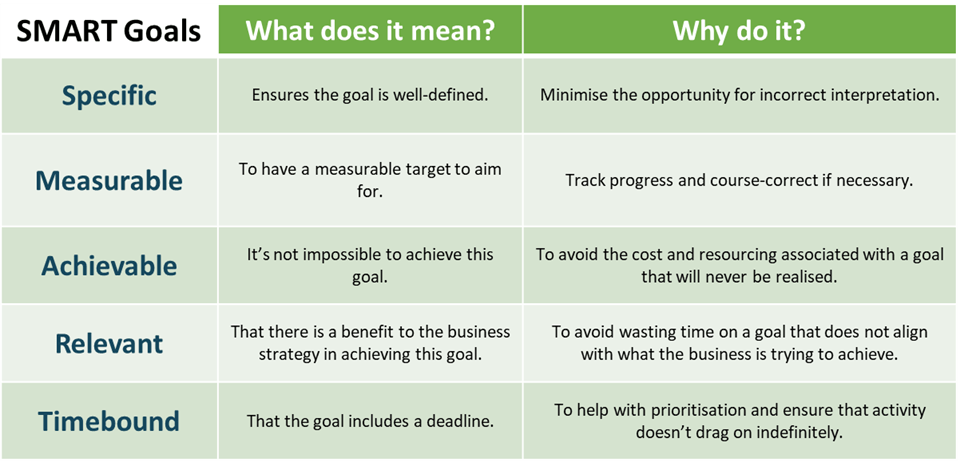

Referring back to Figure 1, once our strategy has been agreed and we’ve selected the cost reduction opportunities that we wish to pursue, the next step is to capture these in our business goals and objectives. Business goals are what the business intends to do and when they plan to have it done by. Business objectives are specific results that the business wishes to achieve. Most top modern-day businesses tend to encapsulate both goals and objectives together using the SMART format. SMART is an acronym for Specific, Measurable, Achievable, Relevant and Timebound. The benefit of using the SMART format is that goals tend to be clearly defined and well thought out, providing a sense of clarity and direction that makes success more likely. Figure 3 below defines SMART goals.

Figure 3: SMART Goal definition.

Below are good (SMART) and bad examples of a goal for a manufacturing company that has called out a reduction in variable overhead costs as part of its strategy:

- Good (SMART): Improve the yield of aluminium used in the beverage can line to 95% versus last year’s average rate of 90% before 30th June 2022 without adverse consequences to overall cost, quality or customer service.

- Bad: Get better material yields.

As you can see, there is a big difference in the clarity and direction of the SMART goal. The SMART goal is specific, calling for a yield increase and specifically calling out aluminium material and the beverage can line. It is measurable – needs to move to 95%. It is achievable (not looking for zero scrap or a yield greater than 100%). It is relevant because material is a variable overhead cost, something the company wishes to reduce as part of its strategy. Finally, it is timebound - needs to be done by 30th June 2022.

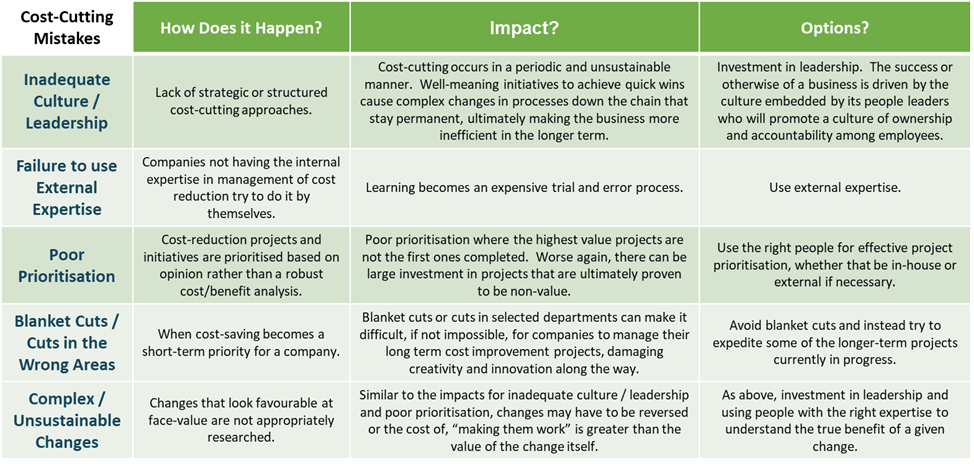

Cost Cutting Mistakes

Figure 4 below lists some of the mistakes that a company can make while attempting to cut costs. While some of these measures may seem appropriate at face value and may even work in short bursts, by their nature they are unstructured and the results can be unintentionally detrimental to the business.

Figure 4: Cost-Cutting Mistakes.